New Tool Improves Drillout Efficiency, Shows High Performance in Initial Runs

Workover Solutions (WOS) is dedicated to consistent improvement across all facets of its business. Drillout efficiency, which is simply how fast and effectively obstructions can be removed from a wellbore after the completion of drilling and cementing, is regularly analyzed by WOS and now has led to the development of a new, improved tool.

The WOS team upgraded several aspects of its already successful 3-1/8” size POWR Motor. The 3-1/4” 8BPM Motor Line, called The Judge, replaces the legacy 3-1/8” POWR motors for WOS fleet.

WOS engineered and manufactured PowR downhole motors are the product of years of data and development in the drillout sector.

By developing The Judge, WOS has improved plug drill times and wash times, prevented premature motor trips, and enhanced operational efficiency in drillouts. The proven results, after thousands of runs, highlight The Judge as a more reliable, higher performing and cost-effective solution for WOS customers.

Customers looking for a motor engineered for high torsional and tensile ratings and better flow areas around transmission and diverter will find those features within The Judge.

The motor has also combined transmission housing and upper bearing housing into one part to eliminate a thread connection below stator. The Upper Radial Bearing is a separate bushing (which was also done on the legacy 2-3/8” motor) and the wear component is now a separate piece.

The Judge, which was made in the USA and is patent pending, offers increased torque capacity through drive train and is available in all standard connections in various sizes.

Additional Features and Accessories of The Judge include:

- Integrated rotor catch

- Multiple power sections options

- Flexible subs built into tools to add in bending

- Hard banding top sub to reduce (outer diameter) OD wear

- Specialty motors available for application up to 8bpm

- Finite Element Analysis (FEA) performed on all parts to reduce fatigue conditions

- Made with high grade alloy components

- WOS High Flow Check Valves; WOS AV Sub; WOS Flex Sub; WOS PulverizR Bits; BitSavR; and WOS EaZy Drill

The Judge Case Study – Results in Action

The Judge was utilized in a field trial by a Marcellus operator in West Virginia for frac plug drillout operation on a six-well pad. The high plug count (124 composite plugs) in the long lateral section (24,116 feet) posed a significant challenge to bit and tool life. There was also potential high friction and hole cleaning issues to manage, and pre-well modeling projected difficulty reaching total depth (TD) on most wells.

Well A presented with a shallow TD, so The Judge was the motor of choice, drilling all 37 plugs successfully to a 21,500’ TD.

On Well B, the 3-1/8” motor was utilized first, but tripped after plug 47 for a bit change due to a tight spot in the casing. After bringing in The Judge, the 71 remaining plugs were drilled to a 30,455’ TD.

On Well C, The Judge was employed to drill out 81 plugs successfully to 30,455’ TD.

It was back to the 3-1/8” motor for use on the wells D and C drilled out.

Excluding the partial run on Well B, The Judge increased torque output and torsional yield strength; reduced internal wear on radial bearings, driveshaft, and flexshaft; and improved durability from fewer housing connections.

“The Judge Motor line represents the next evolution of WOS engineering and performance,” said Mark Miller, Chief Executive Officer of Workover Solutions. “Our team took years of data, field experience, and customer feedback to design a motor that sets a new standard for durability, efficiency, and power in drillout operations. The Judge not only improves plug and wash times but also enhances overall reliability, reducing downtime and cost for our customers. It’s a testament to what’s possible when innovation is driven by real-world performance.”

Why Should Customers Work with WOS

Durability and Productivity: WOS motors consistently show reliability, perform above standards and help drive down costs. Customers can enjoy less non-productive time and fast, clean mill outs.

Record Setting Results: WOS motors hold numerous records for time in hole and plug count drilled out in a single run. The Judge has been utilized on all WOS record-breaking high plug count and long lateral applications.

In-House Expertise and Support: WOS offers proprietary motor design, wholly manufactured, serviced and supported in-house by WOS engineers and technicians. All motors are dyno tested before heading to location ensuring stated motor performance.

The WOS team is here to answer your questions and provide you with additional information in your quest to secure the most reliable downhole tools. To get the conversation started, contact your local WOS representative, give us a call on our main line at 346-774-4433, or email us at sales@wos.com.

Product Details – 3-1/4” Motor – The Judge:

Tools Size, in 3.25 (versus 3.13 for 3-1/8”)

Overall Tool Length: 177 in (versus 155 in for 3-1/8”)

Makeup length, ft 14.83

Lobes 4 / 5

Stages 3.0

Flow rate, bpm 4 to 8

Full Load Differential, psi 750

TQ Output 2,400

Full Load Bit Speed, rpg 1.58

Weight, lbs 269

Torsional Yield: 3,800 Ft-LBS (versus 2,800 Ft-LBS for 3-1/8”)

Top Connection 2-3/8” REG Box

Bottom Connection 2-3/8” REG Box

Application Overview:

Target Formation: NWV Marcellus Shale

Operation: frac plug drillout

Date: June 2025

Tool Conveyance: 2-7/8” jointed stickpipe

Production Casing: 5-1/2” OD 23 lb/ft

Plug MFR’s: Nine, Yellow Jacket, SLB

Plug Types: Composite, Dissolvable

Avg Plug Count: 112

TVD Avg: 7,093 ft

Fluid: Freshwater

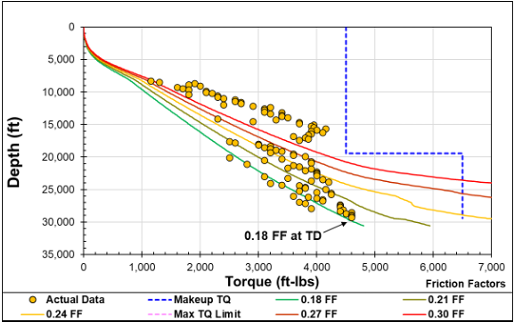

Well C Drillout – Depth vs TQ:

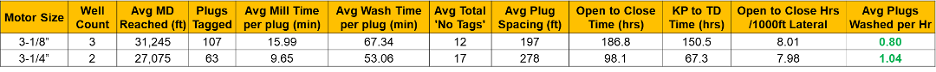

Pad Performance Metrics by Motor Size: