Workover Solutions WellSoniX Ultrasonic tool provides direct measurement of casing integrity and cement evaluation

Casing and tubulars face significant risks from wear, corrosion, and structural defects stemming from manufacturing flaws or mechanical damage caused from wireline operations. These could lead to operational nightmares, catastrophic failures, and safety hazards.

Wall thinning, material degradation, replacing equipment components and weakened wellbore integrity can increase maintenance costs, create environmental hazards, and potentially put your workers, and the general public, in harm’s way.

Workover Solutions (WOS) is determined to mitigate the risks associated with casing and tubulars with robust inspection protocols, ensuring the right materials and tools are utilized for specific environments, and employing the correct preventative measures.

How To Lessen Structural Defects in Tubulars

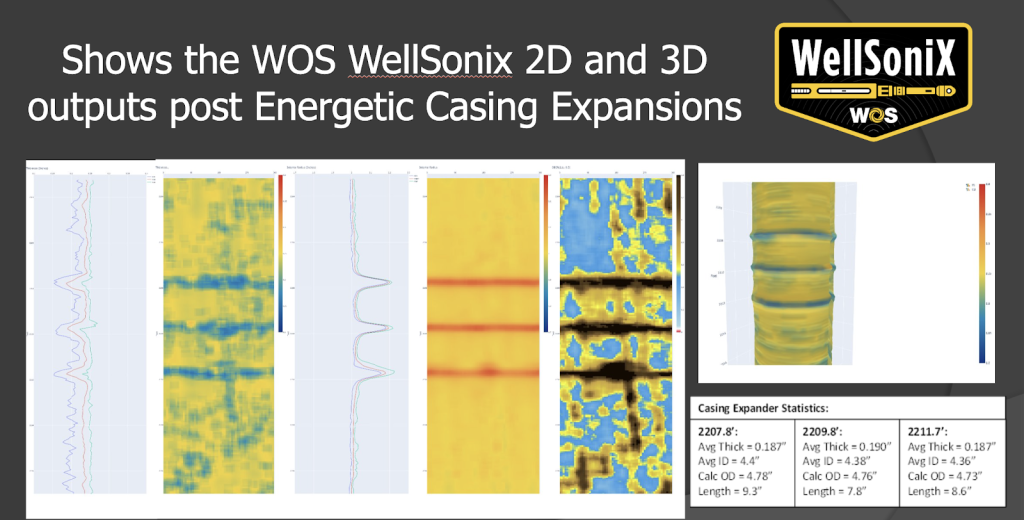

The WellSoniX tool focuses on detecting wear, corrosion, and structural defects in tubulars by identifying both internal and external anomalies and accurately measuring wall thickness to assess burst and collapse pressure thresholds.

This data supports risk analysis and operational decisions throughout the well’s lifecycle.

Proactive monitoring and adherence to the highest safety standards (API RP 1170 and 1171) are critical to minimizing dangers associated with tubular degradation. They are also directly aligned with the core values at WOS: Safety, Integrity, and Innovation.

How to Enhance Well Integrity

Complementing casing inspection is a cement evaluation, utilizing acoustic impedance measurements to identify the material behind the casing, distinguishing between cement, fluid, or gas, and provides circumferential analysis to determine cement coverage. It also detects channels and voids that may jeopardize zonal isolation.

With multiple levels of diagnostics available, WellSoniX, the latest Ultrasonic technology from WOS, establishes safe, long-term performance of the wellbore and effective barrier integrity. This data supports the already robust risk analysis and existing operational adjustments our on-site team makes to maintain superior performance throughout the well’s lifecycle.

WellSoniX is:

- Transformative, for operators in need of casing integrity inspection and cement evaluation logs looking to save costs and enhance efficiency.

- Accurate, delivering high-resolution 360° wall thickness measurements and internal geometry mapping, defining internal versus external corrosion and defects identifying defects as small as 0.079” OD, honing an industry-leading accuracy of 0.004” on both ID and wall thickness.

- Smart, offering direct measurement which eliminates identification of ambiguous shape and size defects while a cement evaluation is completed in the same run.

- Innovative, redefining casing and cement evaluation with unmatched precision and versatility.

Benefits of WOS WellSonix Ultrasonic tool

An ultrasonic tool that works in dynamic downhole conditions.

WellSoniX is designed to evaluate tubulars ranging from 3.5” to 9.625” OD and provides real-time environmental corrections using a time-of-flight fluid velocity sensor, delivering accurate results, even in dynamic downhole conditions.

An ultrasonic tool with a compact design.

WellSoniX presents a compact design, ideal for navigating restrictions, and flexible deployment via slickline, wireline, or tubing, eliminating ambiguity in defect identification, differentiating internal from external corrosion, and delivering valuable insights needed to make confident and data-driven decisions.

An ultrasonic tool that optimizes well integrity.

The WellSoniX cement bond log capabilities allow operators to pinpoint voids, channels, and debonding, offering a comprehensive view of casing and cement integrity all in a single run.

WellSoniX gives operators clarity and accuracy they can trust when it matters most. Reach out to us today for more information or to request a conversation with our sales team.

When to use WellSoniX:

Casing Integrity Inspection

- Detect and monitor wear and corrosion of tubulars

- Locate and characterize internal and external defects or deformation

- Measure tubular wall thickness for collapse and burst pressure calculations

Cement Evaluation

- Measuring Acoustic Impedance of material behind pipe (Cement, Fluid, Gas)

- Evaluating circumferential distribution of cement

- Identifying location of channels or voids

WellSoniX Tool Features:

- High resolution 360° direct wall thickness measurement and internal geometry mapping (caliper equivalent)

- 60 ID and thickness measurements per revolution

- Operates at 180 rpm

- Accurately identify defects as small as 0.079” OD

- Accuracy: ID = 0.004” and Wall Thickness = 0.004”

- Cement bond log capability to identify voids, channels, and debonding

- Capable of logging 3.5” to 9.625” OD tubulars

- Real time environmental corrections using fluid velocity from time-of-flight sensor

Tool Benefits:

- Direct measurement eliminates identification of ambiguous shape and size defects

- Memory tool can be conveyed on slickline, wireline, or tubing

- Casing integrity and cement evaluation completed in same run

- Define internal versus external corrosion and defects

- Small OD design to negotiate restrictions capable of logging 3.5” to 9.625” OD tubulars

Accessories

- Gamma Ray

- Magnetic Collar Locator

- External probe temperature measurement

- Caliper logs