Workover Solutions (WOS) is in relentless pursuit of downhole drillout perfection. Removing debris after drilling ensures the stability and efficiency of the wellbore for long-term success.

The WOS InterrogatR downhole memory sub allows placement of high frequency sensors directly in the drill string during the intense bottomhole environment of frac plug drillout operations. The tool increases BHA reliability, BHA optimization, and provides a basic production log, all at an affordable price point.

The self-contained sub records pressure, temperature, RPM, and 3-axis shock to its on-board memory for post-job data retrieval and analysis. This data allows for better decisions for weight on bit (WOB) considerations, increasing efficiency on BHA selection, plug selection, pump considerations, procedural changes for drill outs, and reducing the amount of fishing jobs.

The memory sub utilizes robust electronics, fittings, and housing designed specifically for WOS tools and drillout operations.

Advanced features of The WOS InterrogatR downhole memory sub include:

- Extended battery life at 300 hours of run time (constantly improving.)

- Pressure activation trigger; leaving no room for the tool to be prematurely activated until inside the well and drilling. No erroneous data is recorded.

- Redundant dataset recording, which permits high confidence in operational success with no intervention from wellsite personnel.

The WOS InterrogatR downhole memory sub continues to prove its worth with valuable data we are collecting on the forces our record setting Bottom Hole Assemblys (BHAs) are encountering.

Our data has revealed information about the effect of pipe on pipe (starting PoP early drastically reduced wash times) and wellbore geometry (traveling up dip vs. down dip, progress slowed significantly during downhill portion of lateral), as well as ERT/agitator vibrations and the effects it has on tools, basic production logging on the way out of the well from temperature logging, and the effects of various drill bits vibrations on the BHA.

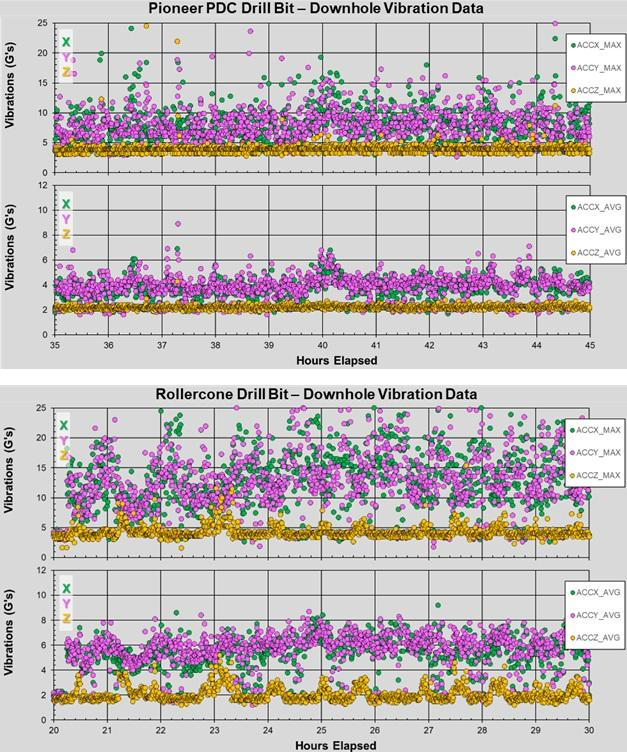

During our latest runs, we compared the downhole vibrations we see at bit with a PDC vs. Tricone. Vibrations are what weaken and cause reliability issues in high plug count and long lateral wells, and WOS has observed a significant reduction in downhole vibrations while running PDCs.

We are observing the PDC (left) sticking to the plug and a reduction in bouncing up and down especially when speaking about the harsh outliers when running a tricone (right). This matches with the vibrations observed on the formation drilling side when running a PDC vs Tricone. We also observed a tighter cluster of data on the X and Y axis which characterize side-to-side movement.